GMP Modular Clean Room Window

Product Description

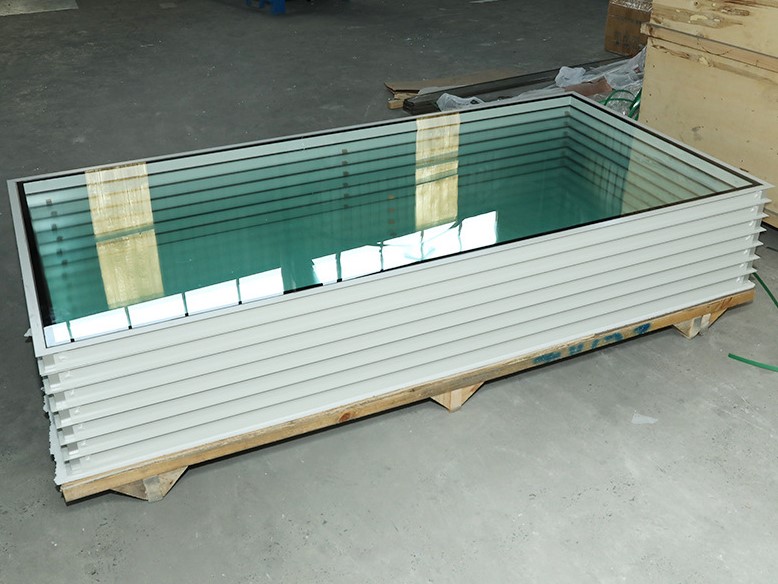

Double-layer hollow tempered glass clean room window is manufactured by fully automatic production line. The equipment automatically loads, cleans, frames, inflates, glues and unloads all mechanized and automatic processing and molding. It adopts flexible warm edge partitions and reactive hot melt which have better sealing and structure strength without mist. The drying agent and inert gas are infilled to have better thermal and heat insulation performance. Clean room window can be connected with handmade sandwich panel or machine-made sandwich panel, which have broken the disadvantages of traditional window such as low precision, non-hermetically sealed, easy to mist and is the best option of clean room industry.

Technical Data Sheet

| Height |

≤2400mm(Customized) |

| Thickness |

50mm(Customized) |

| Material |

5mm double tempered glass and aluminum profile frame |

| Infill |

Drying agent and inert gas |

| Shape |

Right angle/round angle(Optional) |

| Connector |

“+” Shaped aluminum profile/Double-clip |

Remark: all kinds of clean room products can be customized as actual requirement.

Product Features

Nice appearance, easy to clean;

Simple structure, easy to install;

Excellent sealing performance;

Thermal and heat insulated.

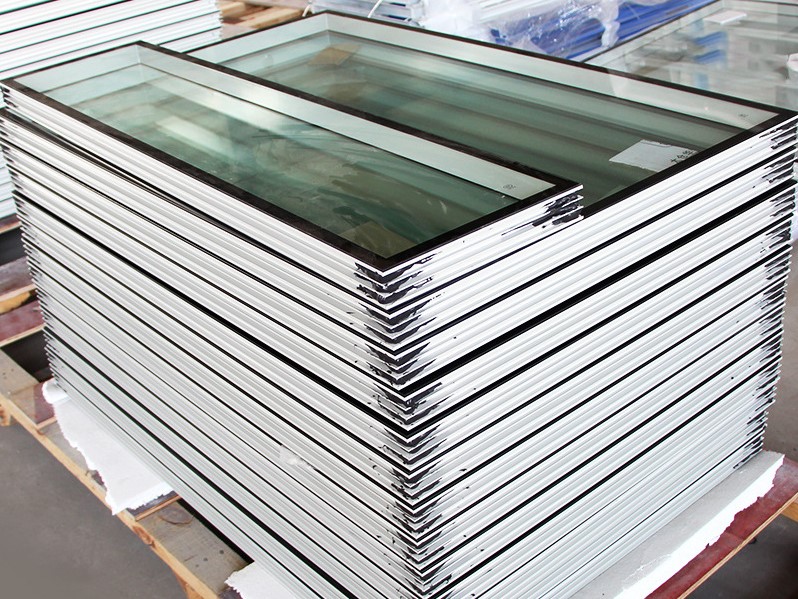

Product Details

Application

Widely used in pharmaceutical industry, hospital, food industry, electronic industry, laboratory, etc.

FAQ

Q: What's the material configuration of clean room window?

A: It is made of double 5mm tempered glass and aluminum profile frame.

Q: Is your clean room window flush with walls after installation?

A: Yes, it is flush with walls after installation which can meet with GMP standard.

Q: What's the function of cleanroom window?

A: It is used to observe people how to work inside clean room and also make clean room more bright.

Q: How do you pack cleanroom windows to avoid damage?

A: We will separate its package with other cargso as possible. It is protected by internal PP film wrapped and then stack into woode case.